The Perfect Solution for Thermal Analysis and Safety

Understanding and managing thermal processes is critical for innovation and safety in industries. At Enthalpy Labs, we offer comprehensive analysis and consulting services for all levels of thermal risk and reaction management.

Heat Flow Analysis

Comprehensive assessment of reaction heat profiles to ensure safe scaling in industrial processes.

Process Safety Optimization

Tailored safety protocols to prevent thermal hazards in chemical production.

Deep Analysis

In-depth analysis of materials under controlled thermal conditions for accurate stability data.

Risk Assessment Consulting

Detailed reports and recommendations to support compliance and safe operations.

Thermal Kinetics Modeling

Advanced modeling for predicting reaction behavior and optimizing processes.

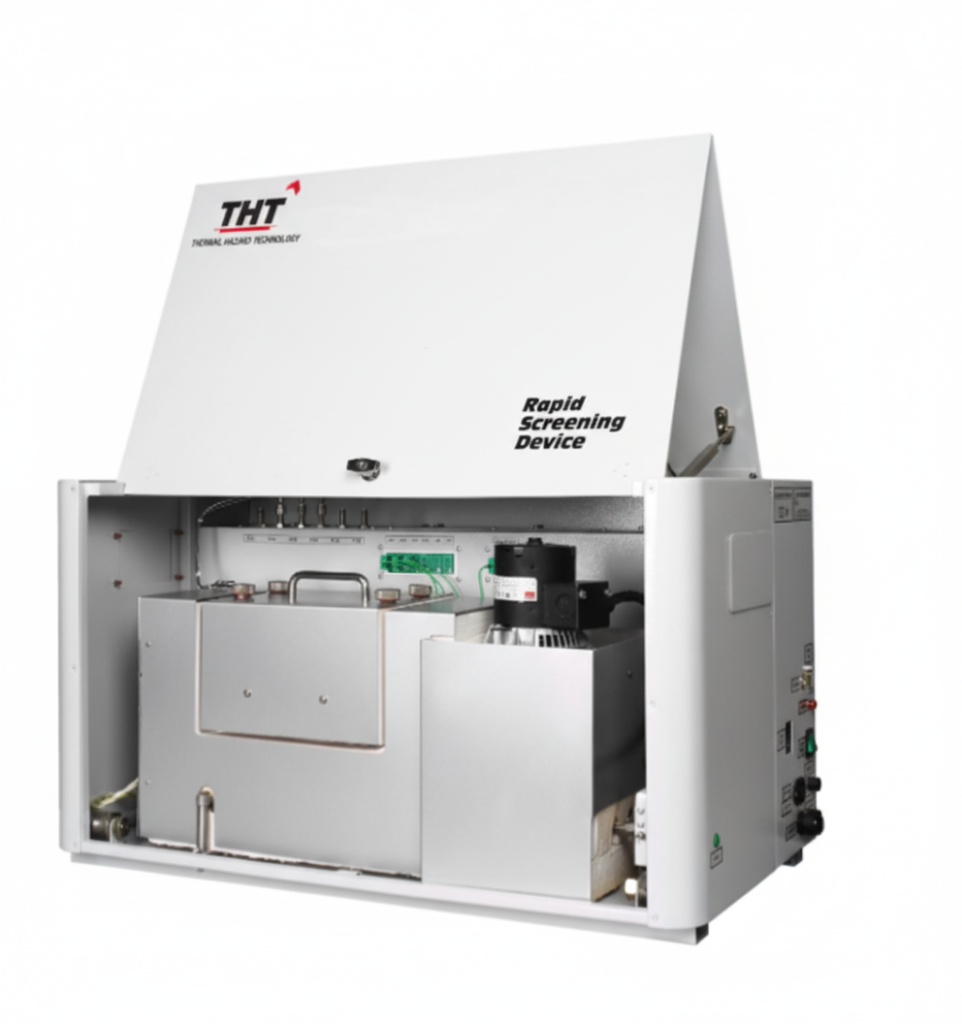

Custom Equipment Solutions

Guidance on selecting and calibrating equipment for specific thermal analysis needs.